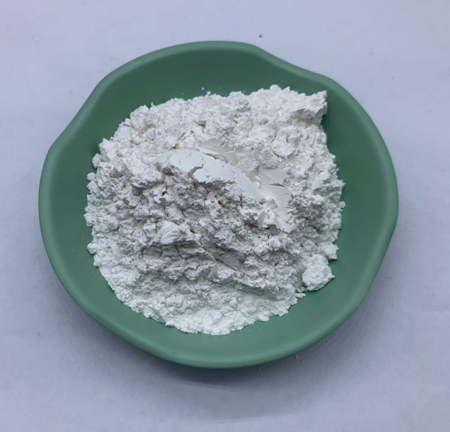

Precipitated silica is an amorphous silicon dioxide powder produced through a wet chemical precipitation process. It features high porosity, large surface area, and low bulk density, making it ideal for a variety of industrial uses — including tires, plastics, coatings, agrochemicals, toothpaste, and animal feed.

Production Method: Wet Precipitation

KosNature manufactures precipitated silica using a controlled chemical process:

Basic Reaction:

Na₂SiO₃ (Sodium Silicate) + H₂SO₄ (Sulfuric Acid) → SiO₂ (precipitated) + Na₂SO₄ + H₂O

Process steps include:

- pH Control

- Reaction temperature & dosing rate optimization

- Gel aging, filtration, and drying (e.g., spray drying)

- Particle size and structure adjustment via milling

This process ensures consistent product quality and allows for specification customization.

Key Product Characteristics

| Property | Description |

|---|---|

| Appearance | White amorphous powder |

| Oil Absorption | 150–300 ml/100g |

| BET Surface Area | 100–300 m²/g |

| Bulk Density | 0.05–0.30 g/cm³ |

| Particle Size (D50) | 3–25 μm (adjustable) |

| pH (5% solution) | 5.5–7.5 (adjustable) |

| Moisture Absorption | High, can be hydrophilic or modified |

| Chemical Behavior | Inert, non-toxic, odorless |

Applications

🛞 Rubber & Tire Manufacturing

- High reinforcement for tread compounds

- Improves wet grip and rolling resistance

- Replaces carbon black in non-marking applications

🧴 Plastics & Composites

- Enhances dimensional stability and rigidity

- Anti-blocking and matting for thermoplastics

- Used in PVC, PE, PP compound formulations

🎨 Paints, Coatings & Inks

- Provides thickening, anti-settling, and matting

- Improves abrasion resistance and suspension

As a leading precipitated silica manufacturer, KosNature offers high-purity, customizable solutions for global tire, plastic, and coating industries.

Request a free sample or quotation