How to Understand the Difference Between Amorphous Silica and Silicon Dioxide in B2B Sourcing

KosNature is one of the trusted silica manufacturers delivering tailored solutions across diverse sectors. Whether you’re sourcing for industrial composites, food-grade stabilizers, or cosmetic textures, our silica products meet the highest standards of safety, quality, and compliance.

Meta Description: Learn how amorphous silica and silicon dioxide differ in structure, function, and industrial usage—crucial insights for B2B silica sourcing in 2025.

Uvod

If you’re in charge of sourcing silica materials for your company, you’ve likely come across terms like amorphous silica i silicon dioxide (SiO₂). At first glance, they might seem interchangeable. But in sourcing—especially in food, kozmetika, or high-performance materials—that assumption can cost you.

I’ve had buyers confuse the two and end up with non-compliant raw materials or ineffective product performance. So in this guide, I’ll walk you through what makes these materials similar, what sets them apart, and how to choose the right form for your industry.

What Is Silicon Dioxide?

Silicon dioxide (SiO₂) is a compound made of silicon and oxygen. It’s one of the most abundant materials on Earth and appears naturally as quartz, sand, or even in living organisms like plants and algae.

In industrial settings, it can be either crystalline (structured) or non-crystalline (amorphous).

When you hear the term silicon dioxide in food or pharmaceutical applications, it often refers to its role as an additive—usually under the code E551.

Key points:

- It’s chemically stable, non-reactive, and safe in food-grade quantities.

- Naturally found in many forms—quartz, silica sand, or diatomaceous earth.

- Its function depends heavily on whether it’s crystalline or amorphous.

What Is Amorphous Silica?

Now here’s where things get more specific.

Amorphous silica refers to non-crystalline silicon dioxide. This means the molecules don’t line up in a regular, repeating pattern. Think of it like a pile of sand versus a stack of bricks.

It’s typically produced synthetically through:

- Fumed (pyrogenic) zemlja kremenja – made by burning silicon tetrachloride in hydrogen and oxygen.

- Precipitated silica – created by reacting sodium silicate and sulfuric acid in water.

- Colloidal silica – a stable suspension of fine amorphous silica particles in water.

Why does this matter? Because amorphous silica is the siguran form used in food, pharma, and cosmetics. Crystalline silica, on the other hand, can be dangerous when inhaled in large quantities.

Benefits of amorphous silica:

- Non-toxic and non-carcinogenic

- High surface area (great for absorption)

- Versatile in form: puder, gel, or slurry

Key Differences Between the Two

1. Structure

- Silicijev dioksid is the chemical formula.

- Amorphous Silica describes a specific structure—non-crystalline.

All amorphous silica is silicon dioxide, but not all silicon dioxide is amorphous.

2. Safety & Regulatory Status

- Amorphous silica is GRAS (Generally Recognized As Safe) by FDA.

- Crystalline silica (like quartz) is regulated due to its respiratory risks.

- E551 is the approved food code for amorphous silica.

3. Labeling & Sourcing Risk

- Some suppliers just say “silicon dioxide.” You must clarify if it’s amorphous—especially in food and cosmetics.

- Not doing so could result in non-compliance with EU/US regulations.

4. Application Impact

- Crystalline forms don’t disperse or absorb like amorphous grades.

- In cosmetics, you need microspheres or fumed silica for that light, silky finish.

- In food, you need fine amorphous particles to prevent clumping (anti-caking).

Industrijske primjene & Use Cases

Hrana & Piće

- E551 used as anti-caking in powders like spices, supplements, and creamer.

- Must be amorphous and food-grade.

Kozmetika

- Amorphous silica beads or microspheres help with matte finish, oil control, and soft-focus.

Rubber & Plastics

- Precipitated silica enhances grip in tires and tensile strength in rubber.

- Often used as a filler ili reinforcing agent.

Coatings & Inks

- Fumed or colloidal silica for rheology control and anti-settling.

Step-by-Step Guide: How to Choose the Right Form

Step 1 – Identify the Function

What role does the silica need to play?

- Absorbent? → Fumed or precipitated

- Anti-caking? → Food-grade amorphous

- Gloss control? → Microspheres

Step 2 – Check Compliance

- Hrana? Look for E551, amorphous, FCC-approved

- Kozmetika? Verify INCI name, particle size, non-nano status

- Industrial? Safety data sheets and REACH certification

Step 3 – Match Performance with Budget

- Fumed silica = higher cost, higher performance

- Precipitated silica = more economical for bulk use

- Silica beads = premium feel, higher price

Bonus Tips

- Ask for the BET surface area—it shows absorption power.

- Always get a COA (Certificate of Analysis) showing amorphous structure.

- For export: make sure the silica is REACH, FDA, and Prop 65 compliant.

Conclusion

Now you know the difference.

What started as a simple “which silica do I buy” question turns out to be a pretty layered decision. You’ve learned how amorphous silica fits into safe, high-functioning applications, and how silicon dioxide is more of a broad umbrella.

Next time a supplier sends you a silica spec sheet, you’ll know the right questions to ask.

Tailored Silica Solutions by Industry Use

At KosNature, we’re a professional silica materials manufacturer, delivering application-driven solutions across key sectors. From industrial reinforcements to cosmetic textures and food-grade performance, our silica products are engineered for precision, safety, and compliance.

🥣 Food & Nutraceuticals

Food-safe and compliant for ingredient performance and stability:

Silicijev dioksid (E551) – anti-caking agent in spices, powders, blends

Food Grade Silica – used in supplement manufacturing and tableting

Colloidal Silica – used in beverage clarification and functional fluid systems

🧴 Cosmetics & Personal Care

Designed for a smoother, cleaner skin feel and formula performance:

Silica Beads – spherical exfoliants for soft cleansing

Micronized Silica / Microspheres – oil absorption, matte effect, soft-focus

Spherical Silica – enhances glide, non-oily finish, and texture consistency

🔧 Industrial, Rubber & Paper

Engineered for strength, stability, and processing efficiency:

Precipitated Silica – high-surface area filler for rubber, plastics, and coatings

Fumed Silica (Pyrogenic) – ultra-fine, anti-settling and rheology modifier

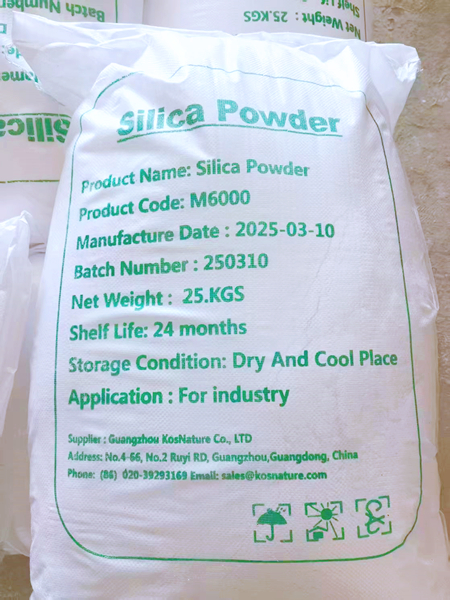

Silica Powder / Filler – bulk additive for improved body and durability

Amorphous Silica – versatile, non-toxic, chemically inert

Hydrophilic / Hydrophobic Silica – customizable surface properties for optimal dispersion or repellency

Explore KosNature’s full range of amorphous silica solutions — or contact us to request a tailored sample for your product line.

Contact our team to request a free sample or quotation